RTVS International water day - Interview with Prof. Miškovský

RTVS International water day - Interview with Prof. Miškovský

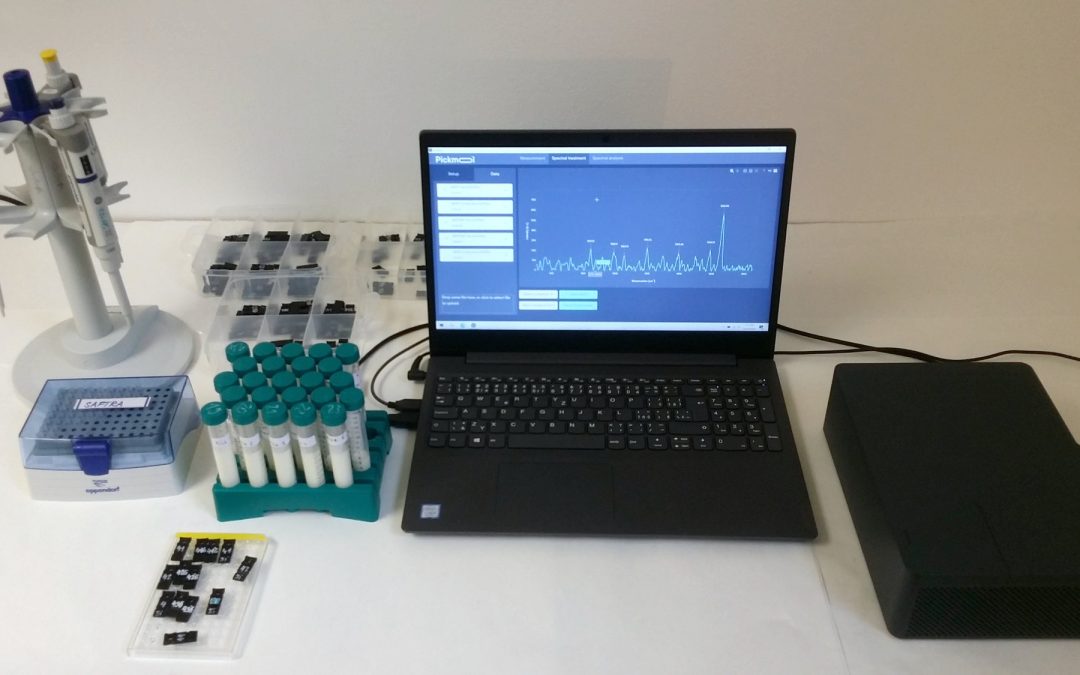

Saftra Photonics performed with support of UNDP, Slovak Aid and Ministry of Foreign and European Affairs of the Slovak Republic water quality monitoring in Republic of Moldova by using its innovative technology PickMol. The PickMol technology a sensor-based...

We are proud to announce that Saftra Photonics Ltd. was chosen by the Slovak government representatives to officially represent the Slovak republic at the DUBAI 2020 EXPO - Climate and Biodiversity Week. Safta Photonics Ltd. and PickMolTM Technology will be presented...

SAFTRA photonics has completed the procedure for the standardisation process of the PickMolTM technology to verify it as an approved reference method for high-sensitive screening of Persistent Organic Pollutants (POPs) (pollutant molecules) in MILK SAMPLES in a mode of MULTIPLEXING ANALYSIS and DIRECT EXTRACTION-LESS DETECTION. The validation tasks were performed according to the “Validation of environmental […]

SAFTRA photonics has already performed the test measurements to provide the procedure for the standardization process of the PickMolTM technology to verify it as an approved reference method for high-sensitive screening of pollutant molecules in milk samples. The measurements were carried out in accordance with validation tasks performed previously according to the “Validation of environmental […]

SAFTRA photonics has also completed the procedure for the standardisation process of the PickMolTM technology to verify it as an approved reference method for high-sensitive screening of Persistent Organic Pollutants (POPs) (pollutant molecules) in water samples in a mode of MULTIPLEXING ANALYSIS. The validation tasks were performed according to the “Validation of environmental test methods […]

Slovak Investment and Trade Development Agency (SARIO) organized on October 24, 2019 Slovak Matchmaking Fair Bratislava 2019. Your current and most prestigious international SARIO events belonging to the strategic activities of SARIO and the Ministry of Economy of the Slovak Republic. Possible CVTIs and SARIOs are also involved in these “Science for Practice” events, involving […]

The 6th annual event of Forbes Technology took place in Bratislava on 26.9.2019. All-day program offered to invited entrepreneurs a chance to communicate what is their main business mission within topic: Innovation in Business 2019. The presentations took the form of moderated speaking on stage. Our PickMolTM technology promotion has been placed in panel “Business is […]

The company has introduced the brand new product design of PickMol RAMASCOPE. The PickMol technology is now represented not only by its unique technology features but also by its unique design. Simplistic approach has resulted in a timeless design language reflecting the core values of the product – reliability, ease-to-use and portability. Also, a new […]

With the ambition to make the pollution monitoring more affordable for developing countries and address any organic pollutants SAFTRA photonics was honored to exhibit at the United Nations high-profile event in Geneva. The bi-annual meetings of the conferences of the Parties to the Basel, Rotterdam and Stockholm conventions took place early May 2019. PickMol by […]

SAFTRA photonics PickMol has completed the procedure for the standardisation of new test method based on plasmonic enhanced Raman scattering for its application in the field of environmental analyses. The validation tasks of new technology were performed according to the “Validation of environmental test methods CEN guide 2013”. The procedure has presented the reliability of […]

Experience the US premiere of the Plasmonic Raman Scattering solution PickMol. The company will exhibit on 19-21 March at the PITTCON 2019 Expo in Philadelphia. Hands-on presentation of the ultra-fast ultra-sensitive solution PickMol with the water quality screening use case will be performed in booth 734 in the New exhibitor area. Book a meeting and personalised […]

Global expansion of SAFTRA photonics has challenged the product name, that has gained multiple successes for the company. Unfortunately, NanoScreen was not a globally protectable trademark. The new name PickMol is a beginning of a new era, when the company has grown from a spin-off to a company economically active on market introducing its solutions […]

Exactly a year ago, SAFTRA photonics has been awarded the FutureNow Startup Awards 2017, the most prestigious Slovak early entrepreneur prize. It has been a great achievement and boost for the company potential. In the period prior to the final event, we experienced the boot camp – a weekend-long gathering of start-ups, mentors and investors. […]

First of its kind analytical detection system for low concentrations of organic substances in water was introduced by SAFTRA photonics. As the company CEO Pavol Miskovsky said, it is a milestone for the worldwide analytical industry. By scaling a complex laboratory for water pollution testing into a suitcase size the detection system brings the […]

SAFTRA photonics environmental solutions will be exhibited on September 19-23 in Shanghai, China. Visitors will have a chance to see a live demo of our novel complete detection system providing results in 5 minutes with a configurable sensitivity up to part per billion. Join us in the Environmental protection and technology hall 4.1H – EU […]

NanoScreen advanced water pollution analytical method was presented at European Innovation Council event co-organized with Procter and Gamble in Brussels, Belgium. This was an excellent networking opportunity to understand the needs of corporates and worldwide impact. We competed in ANALYZE IT pitching contest among another four SME Instrument projects and won it! The audience has […]

The NanoScreen product was selected by the EASME EU agency as one of 15 European promising technologies for water industry. It was exhibited for the first time to the public from 10 to 12 April 2018 at Asia Water Expo in Kuala Lumpur, Malaysia. The booth headline was BE ALWAYS IN CONTROL OF WATER QUALITY […]

As a part of the NanoScreen product strategy, the company has started its active presence on the North American continent. With the kind support of the Slovak-American Foundation the team has participated to two business trips in February 2018. Pavol Miskovsky and Daniel Jancura joined the 62nd Biophysical Society Meeting in San Francisco. Their primary […]

We have done it! Saftra Photonics has become the winner of Startup Awards 2017 – the most reputable competition of early stage businesses in Slovakia. This label of business excellence, coverage by media and prize money of 50k EUR will help us to further develop the NanoScreen product and attract talents for the team. The […]

Saftra Photonics team represented by CEO Pavol Miskovsky and project manager Miroslav Konecny has succeeded in a tough competition and passed to finals of the Startup Awards 2017. Mentors and investors appreciated the business plan and technology excellence of NanoScreen project. Final pitch takes place in Slovak National Theatre on 1 December 2017. Tickets available […]

Recent victory of Saftra Photonics in the Startup Awards 2017 has attracted significant attention of media and investors. Their primary interest was about the product itself – the NanoScreen sensing chip and its long-term vision. But also the story of the team behind and a broader context of activities have got their space. (photo by […]

The project team of Saftra Photonics, RECETOX and CSIC has gathered in Bratislava to kick off NanoScreen project activities. The aim was to introduce team roles, build a team spirit and achieve a common vision of project goals. Project coordinator Pavol Miskovsky has introduced the work plan and its interdependencies. A plan for the first […]

Saftra Photonics has become the first Slovak company to win SME Instruments Phase II since the start of EC programme Horizon 2020. Project will advance the existing prototype of NanoScreen chip by validation in certified lab and allow the market entry in 2019. Planned project costs of 1.7 mil. EUR will be covered by 70% […]